We conduct thorough assessments of land suitability, feedstock availability, and energy demand to create a strong foundation for your Bio CBG project.

Our team delivers customized plant designs tailored to your feedstock and capacity needs, ensuring maximum efficiency and cost-effectiveness.

From groundwork to operational readiness, we handle the complete installation process, ensuring your plant is production-ready on time.

We guide you through government approvals, environmental clearances, and subsidy applications, making regulatory processes hassle-free.

Our experts help you prepare bankable project reports and connect with financial institutions to secure funding for your plant.

We provide specialized support for Napier Grass cultivation, known for its high biomass yield and sustainable growth cycle.

Post-installation, we offer regular maintenance, troubleshooting, and performance optimization to ensure your plant runs smoothly for years.

The Continuous Stirred Tank Reactor (CSTR) is ideal for handling semi-solid biomass and diverse organic waste, ensuring efficient mixing, stable temperature, and optimal microbial activity for biogas production and high-quality organic manure.

Technical Specifications:

- Process Type: Mesophilic Anaerobic Digestion

- Operating Temperature: 32°C – 38°C

- Organic Loading Rate: 10–12%

- Discharge: Liquid Slurry

- By-product: Solid Organic Manure (20–25%)

Feedstock:

- Pressmud

- Cow Dung

- Poultry Waste

- Food Waste

- Vegetable Waste

Efficient Hydrogen Sulfide Removal for Cleaner Biogas & Longer Equipment Life

Hydrogen Sulfide (H₂S) is a common impurity in biogas, landfill gas, and various industrial gas streams. It is toxic, corrosive, and can cause severe damage to gas engines, pipelines, and downstream equipment. Our H₂S Removal Systems are designed to efficiently eliminate H₂S, ensuring safe, reliable, and high-quality gas for use.

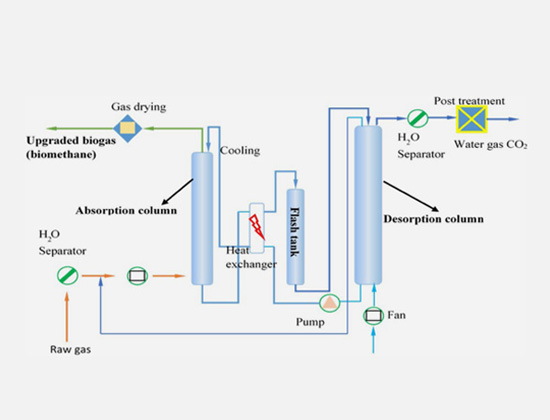

Water scrubbing is used to remove carbon dioxide but also hydrogen sulphide from biogas since these gases is more soluble in water than methane. The absorption process is purely physical. Usually the biogas is pressurized and fed to the bottom of a packed column where water is fed on the top and so the absorption process is operated counter-currently.

Pressure swing adsorption, also known as PSA, is emerging as most popular biogas upgradation technology in many parts of the world. A typical PAS system is compressed of two or four vessels in series that are filled with adsorbent media which is capable of removing water vapour, Co2, N2 and O2 from the biogas stream.

The technology used to separate the two main components of biogas –methane and carbon dioxide – is based on the use of polymer membranes. This efficient system generated biomethane with a methane (CH4) content of between 96.5% and 99% depending on its purpose.

Municipal Solid Waste (MSW) Bio CBG Plants convert city waste into vehicle-grade Compressed Biogas and organic fertilizers. Through waste segregation, anaerobic digestion, and gas purification, we deliver a sustainable solution for urban waste challenges.

Benefits:

- Reduces landfill & methane emissions.

- Produces clean, renewable CBG fuel.

- Generates organic fertilizers for agriculture.

- Promotes circular economy & job creation.

We turn waste problems into green energy opportunities.